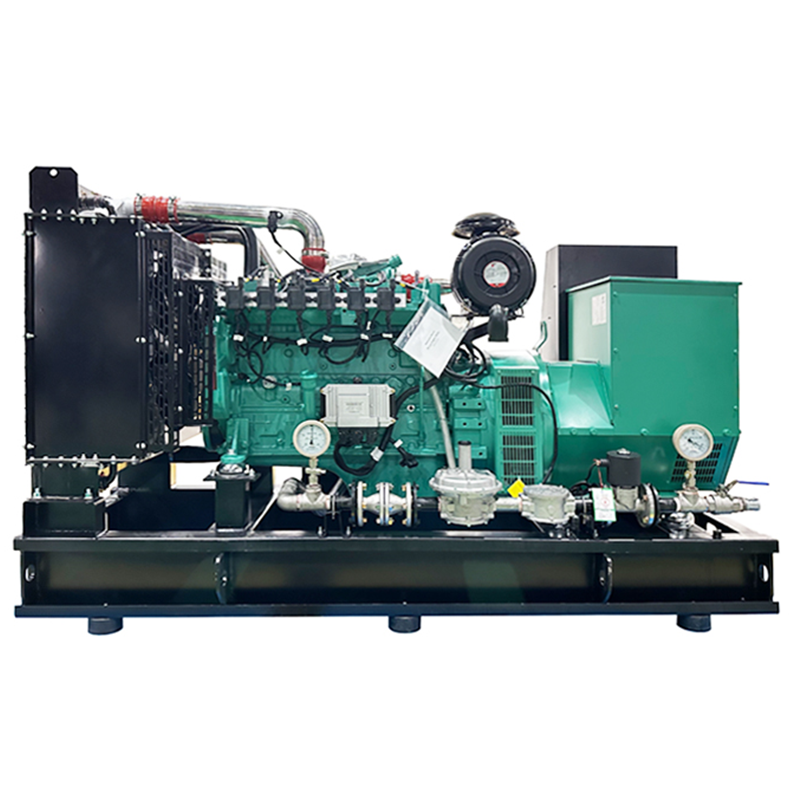

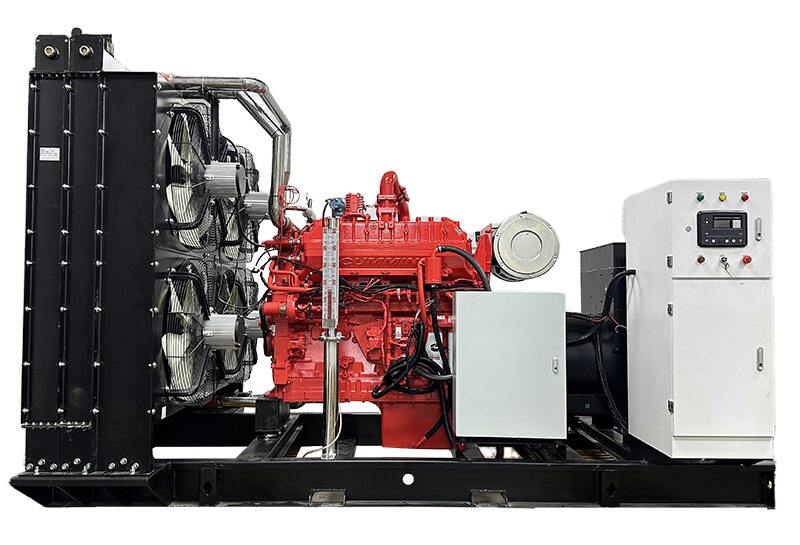

Natural gas generator

Working Principle

Its engine mixes natural gas and air in a fixed ratio via the intake system, sending the mixture into the cylinder. After compression, a spark plug ignites it; the high-temperature, high-pressure gas pushes the piston to drive the crankshaft (thermal energy → mechanical energy). The crankshaft then connects to the generator’s rotor to generate electricity (mechanical energy → electrical energy).

- Overview

- Recommended Products

Structural Features

- Turbocharging & Intercooling: Added to non-supercharged models to boost intake density and engine power.

- Cooling System: Separates high/low-temperature cycles—high-temperature cools cylinders/engine blocks; low-temperature cools supercharged gas/air/oil coolers, maintaining proper engine temperature.

- Ignition System: Typically electronic, with accurate timing and high energy for timely, full natural gas combustion.

Advantages

High efficiency (full combustion, low fuel use); eco-friendly (fewer pollutants than coal-fired power); reliable (quick start, long maintenance cycles); adaptable (suits low-pressure gas, varied gas qualities/environments).

Applications

- Industrial: Oil fields, mines, coking plants (self-provided production power).

- Commercial: Malls, hotels, offices (backup power for outages).

- Power system: Peak-shaving to enhance grid stability.

- Distributed energy: Combined with solar/wind for on-site efficient energy use.