Hydrogen Generator Set

Working Principle

1. Fuel Cell Type (Mainstream)

Hydrogen enters fuel cell anode via supply system (pressure reducer, filter), splitting into H⁺ and e⁻.

H⁺ migrates to cathode via electrolyte membrane; e⁻ forms current (direct power).

H⁺, e⁻ and O₂ combine at cathode to form water (only emission); control system adjusts supply for stable output.

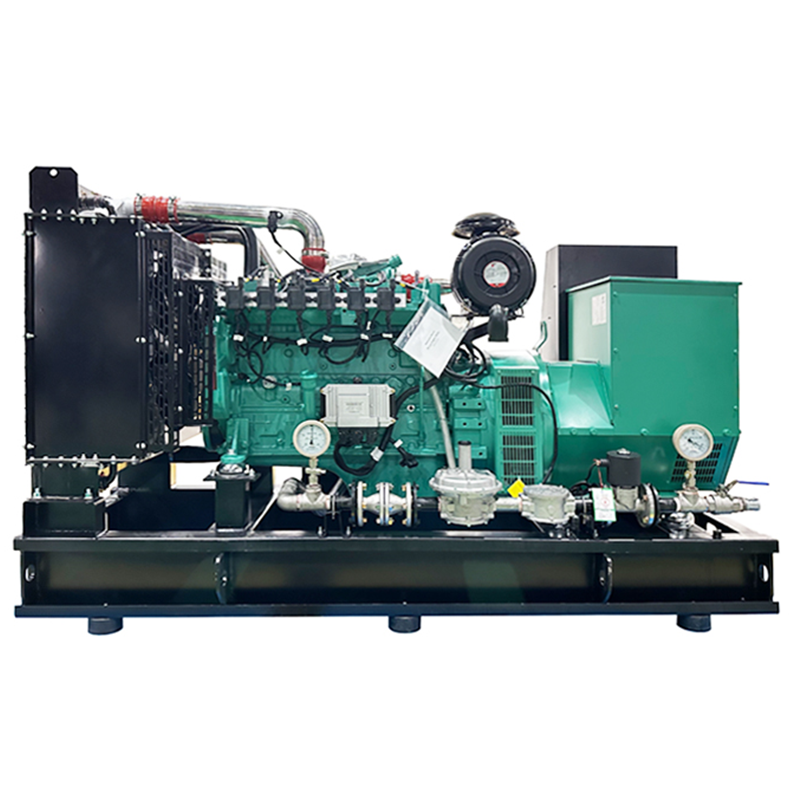

2. Internal Combustion Type

Hydrogen-air mixture enters engine cylinder, compressed, ignited by spark plug.

High-temp/pressure gas pushes piston to drive crankshaft (thermal→mechanical energy).

Crankshaft rotates generator rotor to convert mechanical energy to electricity.

- Overview

- Recommended Products

Core Features

Zero carbon: Fuel cell type emits only water; internal combustion type has almost no sulfur, NOₓ or particulates.

Fuel system: High-pressure tanks (35/70MPa) or low-temp storage + hydrogen leak sensors for safety.

Adaptability: Fuel cell links with solar/wind; internal combustion modifies from natural gas generators.

Pros & Cons

Pros: High eco-friendliness; green hydrogen (from renewables) enables full-life zero carbon; low noise/maintenance.

Cons: High green hydrogen cost; high storage/transport tech threshold; fuel cell life/cost to optimize.

Applications

Energy: Grid peak shaving, distributed stations (e.g., park power).

Transport: Auxiliary power for hydrogen trucks, ships.

Special: Zero-carbon power for remote base stations, aerospace, emergency rescue.