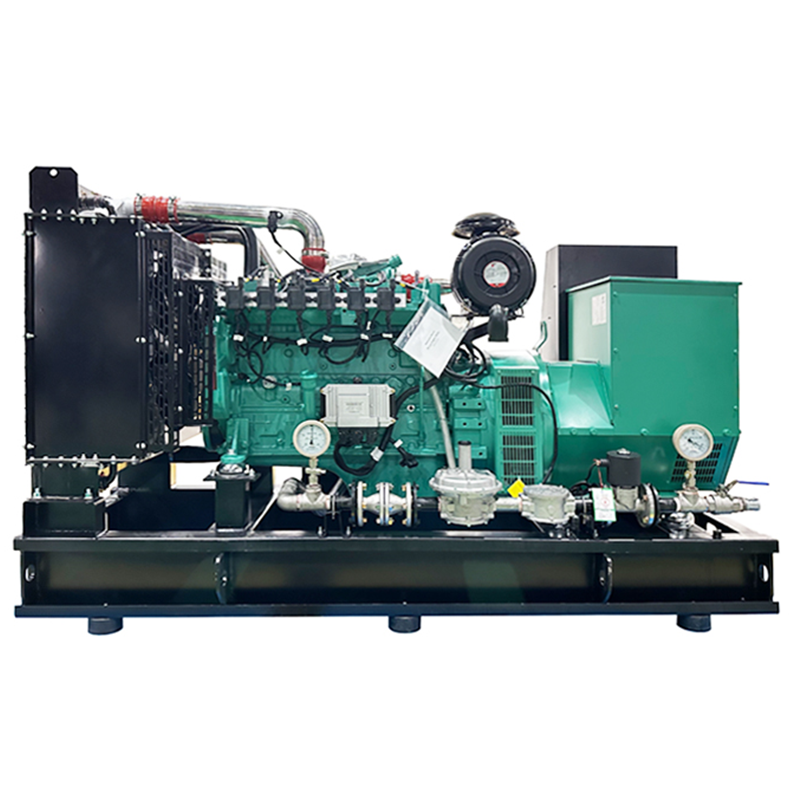

Methanol Generator Set

Working Principle

Methanol is precisely delivered by supply system (filter, injector) and mixed with air in ratio.

Mixture enters engine cylinder for compression, ignited by spark plug (gasoline engine modification) or compression ignition (diesel engine modification).

Combustion’s high-temp/pressure gas pushes piston to drive crankshaft (thermal→mechanical energy).

Crankshaft rotates generator rotor to generate electricity (mechanical→electrical energy); control system adjusts speed, voltage and fuel supply in real time.

- Overview

- Recommended Products

Core Features

Fuel System: Equipped with methanol-specific injectors and anti-corrosion parts to avoid damage from methanol’s corrosiveness.

Adaptability: Mostly modified from gasoline/diesel generators; some support methanol-gasoline dual-fuel switching.

Emission Control: Sulfur-free, low NOₓ combustion; exhaust treatment device needed to reduce formaldehyde emission.

Pros & Cons

Pros: Low methanol price, easy transport/storage; diverse sources (coal, biomass), stable supply.

Cons: Lower energy density than gasoline, shorter range; methanol’s corrosion needs regular supply system maintenance.

Typical Applications

Industrial: Backup power for small/medium factories, temporary power for remote mines.

Civil: Distributed power in rural areas, post-disaster emergency power.

Special: Mobile/small scenarios like communication base stations, RVs.