Understand the Installation Site Requirements First

It is really important to choose and prepare the proper site before beginning the installation of a gas generator set. The site must be flat and big enough to accommodate the generator set and also provide enough space for the people who will be operating and maintaining it. Also, check to see if the site is safe enough, with a proper distance from combustible materials, like tanks of gasoline, wooden piles, or anything else that could catch fire. Gas generators get hot and can be fire hazards if proper care is not practiced. Furthermore, the site must have proper ventilation. Generators must be able to cool and dissipate excess heat during operation, or the overheating will affect their performance. Do not forget to ensure the site is not in a low-lying, easy to flood area. Water in the generator and flooding the site can cause short circuits and damaged equipment.

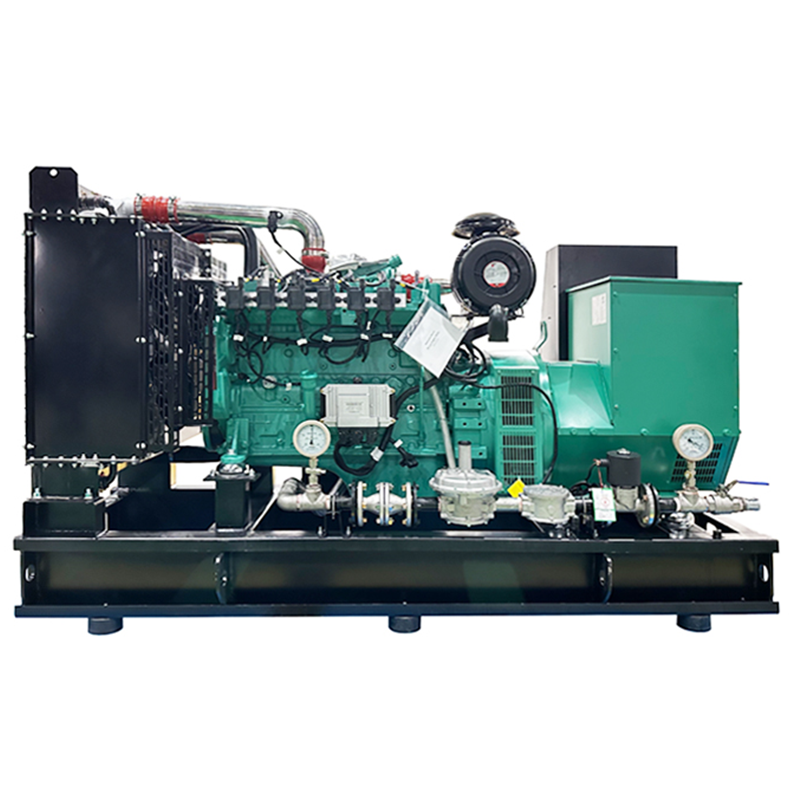

Review All Parts of the Gas Generator Set

Once the site is ready, the next step is the meticulous verification of all the components of the gas generator set. First, see that all the main parts—the engine, gas supply system, control panel, and cooling system—are complete and in good condition. The outer engine casing should have no cracks, and the control panel wires should be tightly connected with no loose ends. Next, check the gas supply system. The pipes and valves should have no leaks, which you can inspect by wiping the joints with soapy water. If no bubbles form, there is no leak. Also, check that the filters in the fuel system are unblocked. If they are dirty, they will obstruct fuel flow and cause poor performance in the generator. It is essential that you do not skip this step, as any of the components have small issues that will cause the generator to malfunction during use.

Important Steps for Installing the Gas Generator Set

To begin the install process, place the gas generator on the prepared, level site and, if necessary, use bolts to anchor it to the ground to keep the generator from moving or excessive shaking when running to keep generator noise to a minimum and help prevent damage to the generator’s internal components. Next, attach the gas supply pipe. Be sure to use properly rated gas supply to prevent leaks, and secure the connections using clamps. After the gas pipe is connected, attach the electric wires. Be sure to pair the corresponding positive and negative poles of the wires, and secure the connection using wire nuts according to the installation instruction. Next, Install the cooling system. For a water-cooled generator, properly connect the water hoses; for an air-cooled unit, install the fan and heat sink as directed. Finally, inspect the engine oil. Insufficient oil, the wrong type or slightly less than the prescribed amount will get the engine to wear out faster.

Do a Test Run After Installation

Don't start using the gas generator right after installation. Test runs help make sure the generator functions properly. The first step is to turn on the control panel. Make sure all the indicators are lit up. After that, start the generator. During the test run, listen to the engine. It should run smoothly. You should not hear knocking, squealing, or any other strange noises. Look at the control panel. The voltage, current, and frequency should be in the range specified in the manual. Let the generator run for at least 30 minutes to an hour. During this time, check for gas leaks in the gas supply system and see if the cooling system is working properly. For water-cooled generators, the water temperature should not be too high. If everything is normal during the test run, the gas generator is ready for regular use. If there are any issues, make sure to turn off the generator and resolve the issues before starting the generator again.

Post-Installation Gas Generator Set Care

No matter how well a gas generator set is installed or how successful the initial tests are, maintenance is key for it to last. For instance, each month the gas supply system should be inspected. Signs of wear or damage should be checked for on the pipes and valves, and replaced. Regularly adjust/change the engine oil usually every 50-100 hours of use is a good standard, and depending on the generator use also oil type. Regularly clean the filters for the fuel and air systems also to keep the generator from inefficient use and system failure or shut down. If the generator has a battery, check it, keep it charged also because a dead battery will be hard to start the generator. Lastly, when a generator has not been used for a while, to keep the fuel system from damaging gas, gas should be drained and stored in a cool, dry place to control the deterioration.

Hot News

Hot News