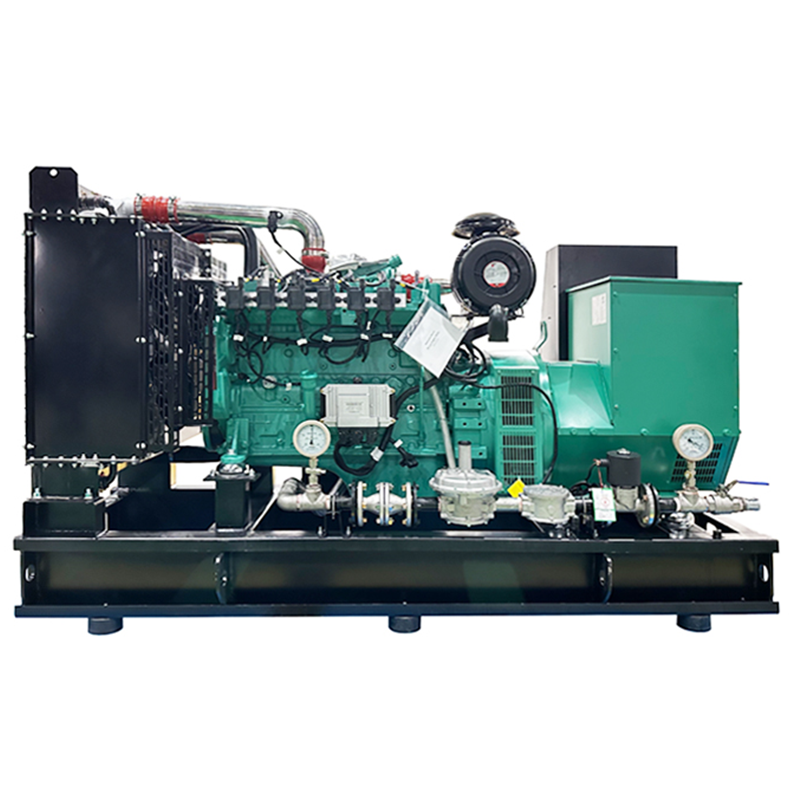

Why Methanol Generators Fit Industrial Needs

There are a number of reasons that set Methanol generators apart in the industrial space. The most important are the environmentally friendly fuel and the robust design of the generators themselves. The fuel can be produced from renewable biomass. This means that industrial users can decrease their carbon footprint. Considering the significance of attaining global carbon neutrality goals, that is a big plus. Furthermore, these generators come with a specialized corrosion resistant fuel system. This design works particularly well with methanol's unique properties and ensures reliable performance in long-term industrial use, where equipment downtime can be particularly costly.

Pre Use Checks for Industrial Methanol Generators

There are 2 important checks to carry out before starting a methanol generator in an industrial setting. First, consider the installation site. It requires adequate ventilation to avoid accumulating fuel vapors. Remember, safety is a primary concern. It also has to be large enough to accommodate the generator and provide access for maintenance activities. Second, the generator's specifications need to align with your power requirements. Evaluate the generator’s power output relative to your facility’s demand. Also, consider how your current power backup systems will integrate. Finally, perform a pre-use inspection of the fuel tank, hoses, and electrical connections to identify any signs of damage. Addressing minor problems will prevent larger issues.

How To Operate an Industrial Methanol Generator

Running an industrial methanol generator should be simple, but to avoid complications and ensure safety and efficacy, it should be done by the book. First, fill the fuel tank with the correct grade fuel methanol and be sure to note the generator’s fuel specifications. Failing to do so will lead to clogging and potential damage to the generator. Next, check the oil and coolant levels and ensure they are within the operational limits. After that, switch the main power button on. Most modern generators are equipped with user friendly control panels. Most will walk you through the various steps, making it simple to get the generator going. After starting the generator, let it idle for a few minutes to allow it to reach optimum operating temperature. This will also ease warm up stress on the engine. After it has warmed up, monitor the temperature, fuel consumption, and power drawn on the generator. If any readings appear strange, immediately shut the generator down.

Maintenance Tips for Lon Lasting Performance

Maintenance for a methanol generator is about continual upkeep. Change the oil and the oil filter. Dirt is the enemy. Periodically clean or replace the air filter. A clogged air filter increases inefficiency and makes the generator use more fuel. The fuel system should be inspected for leaks, and the tank should be cleaned periodically to eliminate and sediment that has built up. Check the fuel for water; methanol will absorb moisture over time; drain water if present. Inspect the battery and any the corroded or damaged electrical wires. Record all of your maintenance. This allows you to track the generator and logically schedule future maintenance.

Following Safety Precautions

When it comes to the usage of a methanol generator in the industry, the safety precautions that should be taken and outlined are imperative. Everyone dealing with or proximity to the generator specifically needs to be able to recognize the risks and be trained on how to properly start and stop the generator. Methanol is flammable and irritant and it is critical to understand its hazards. When utilizing methanol and during its use, the safety goggles and gloves should be worn. If there is a spill, it should be immediately cleaned up using absorbent material. Never smoke or use any open flames near the generator and fuel storage in any case, and clear “No Smoking” signage must be installed. Fire extinguishers should be right beside the generator in case of a flammable liquids fire and the generator serviced properly to avoid electric shocks. Conclusion, emergency shutdown provision should be available and clearly communicated to all staff across the board. Posts on social media that document generator usage should have a clear emergency shut down provision.

Hot News

Hot News