Energy Conservation is a business strategy that impacts an industry’s profitability and regulatory obligations. Energy conservation goals must have an impact on a business's bottom line. As industries figure out how to decrease operational costs while also improving green credentials, the business case for cogeneration becomes clear. But why is it ideal for industrial energy conservation? It is operational Energy Efficiency, Flexibility, and Long-term Value.

Operational Energy Efficiency That Results in Positive Economics

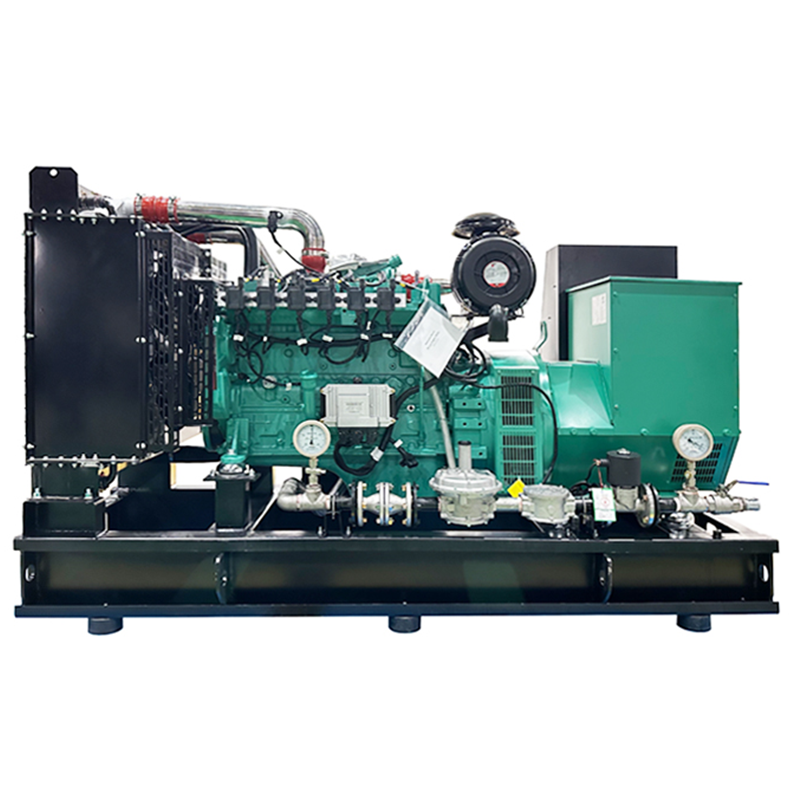

Energy industrial activities burn energy, and traditional energy systems attack input energy and heat. Cogeneration systems capture and reuse non-renewable energy, overcoming the waste. Positive ecologic impacts derive from economic realities. For instance, Keya gas-fired cogeneration systems utilize a technologically optimized engine to substantially reduce non-renewable energy waste and overall energy footprint while providing electrical and thermal energy from fuel combustion.

Fuel costs are a major expense for industrial facilities, and cogeneration also saves costs related spending. Systems that use cleaner fuels like natural gas, LPG, methanol, or hydrogen are less dependent on more expensive and less efficient fuels, such as diesel. Natural gas is a cheaper and more efficient source of fuel, and methanol as a fuel is the greenest as it can be obtained from renewable biomass. Also, hydrogen can lead to fully decarbonized operation of a fuel cell and other systems. A combination of such systems enables businesses to optimize their operations in a way to significantly decrease and stabilize their costs and major spending in a long run.

Environmental Compliance as a Competitive Edge

In the European Union and North America, industry is facing strict environmental compliance in the form of new regulatory frameworks aimed at reducing emissions of NOx, CO, particulates, and sulfur oxides. Emission compliance becomes easier and more cost effective because of the design of Keya cogeneration systems. Low emitting combustion technologies guarantee a low environmental footprint. Further emissions of CO2 are completely removed using hydrogen for cogeneration. Zero CO2 combustion is ideal for businesses pursuing corporare carbon neutrality.

It’s no longer just about regulatory compliances; customers, investors, or any other stakeholders take environmental responsibility into serious consideration. Investing into cogeneration facilities demonstrates further commitment to environmental responsibility and use that to improve their image and brand reputation. Whether it is environmental responsibility or corporate ESG goals, or green incentives, cogeneration provides the opportunity as a competitive advantage.

Customized Solutions for Industrial Diversity

No two industrial facilities are the same. Energy demands, operational conditions, and sustainability goals will vary. This is why customized cogeneration are necessary for maximizing energy conservation outcomes. Keya’s approach to tailored systems is aimed to ensure that every setup is fitted to the specfic needs of a facility, whether small operation or large scale manufacturing.

Everything from a portable LPG system needed for temporary power of an industrial site, a methanol generator set for off-grid applications, to a hydrogen system for providing backup power in urban areas, has a cogeneration solution to match. The one stop service comprising of technical consulting and drawing design, system assembling, commissioning and shipment ensures a smooth and easy integration and commences on maximum system efficiency from day one. Such is the level of customization, facilities are no longer limited to one-size-fits-all solutions but can achieve systems that are in sync with their unique operations.

Uninterrupted Operation Reliability and Durability

Every minute of disruption in an industrial process means an abrupt halt in productivity and revenue. Each of Keya’s cogeneration solutions is designed for seamless, continuous operation even in extremely tough industrial settings. Reliability is one of the most important features of cogeneration systems. These systems are designed to withstand extremely tough environments and heavy loads.

Every system in production goes through extensive testing that the factory records on video and in photos. These records are kept to ensure that all factory standards are kept, and those records are shared with customers. Customers get remote control systems that allow them to monitor during operation. Customers don’t need to maintain systems frequently, outages are rare, and systems deliver energy consistently. These systems are very important for the continued operation of industrial customers to prevent additional costs in their processes.

Through Comprehensive Support, Long-Term Value Is Achieved

The primary value of a cogeneration system is not in the installation but in the longevity of the industrial facility processes. Optimized performance of a cogeneration system for industrial facility partners is a must, and Keya provides this through lifetime after-sales service, supported by the company’s presence in all regions through a network of offices.

In addition, the partnerships with top industry brands mean each component-less cogeneration system will be assembled with components of the highest quality, thus increasing reliability and performance. Customer support and top quality hardware are advantages that are offered to industrial businesses, and should be taken in order to obtain a system which will provide numerous savings and improved efficiency throughout the system's operational life. This shows that cogeneration systems are a worthwhile investment for businesses looking to invest intelligently.

Final Considerations

When and if properly installed, cogeneration represents failed industrial power conservation strategies. Where most failed systems, and the operational strategies, resulted in a loss of operational profit, cogeneration systems produced a radical shift in the operational paradigm. Offering radical operational profit, and operational savings, the integration of cogeneration is a power conservation and industrial operational profit strategy that is without bearing operational and profit risk. The is a power conservation and industrial operational profit strategy that is devoid of linear operational risk and profit risk, and which also vastly improved the operational profit. The is a industrial operational profit strategy which also vastly improved operational efficiency when compared to competing systems.

Hot News

Hot News