Cost Is Optimized On A Budget

Operational costs are always a core interest for industrial enterprises, in which CHP (Combined Heat and Power) systems optimize the cost. CHP systems use clean fuels that are cheaper, such as natural gas, which significantly decrease fuel costs in comparison to more expensive fuels like diesel. In many areas, fuels such as LPG and methanol are also economically priced, which decreases operational costs in the long run. Traditional single-energy systems lose a lot of energy in conversions. CHP systems on the other hand, capture, and use the heat that would otherwise be wasted, which decreases energy costs. This cost effectiveness doesn't just impact the enterprise for the short term, but positively influences costs on a long term basis.

Eco-Friendly Achievement with Zero Emissions

Industrial businesses face continuous pressure to hit emissions targets. Unfortunately for them. they do not have the right equipment. Enter: CHP systems. These systems fail to meet regulations for environmental protection when it comes to units that emit pollutants including, NOx, CO, and far worse, particulates. For instance, the newest hydrogen-powered CHP units have a net CO₂ emission of zero, transacting with green hydrogen during solar or wind oxidative electrolysis. Even the newest systems that run with Methanol and may have biomass that is renewable for fuel have a low emissions intensity. If they are all in on CHP, they can avoid all emissions regulation, and all of the stigma and penalties associated while positioning themselves as a green entity for commercial trade that is global.

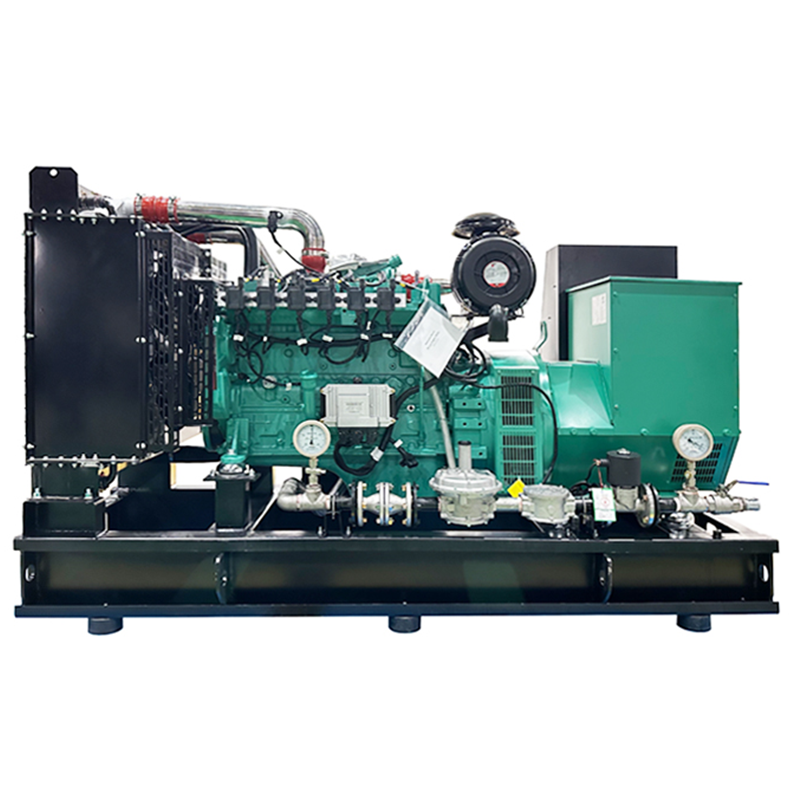

Reliability and Sustainability in Difficult Conditions

During the production of energy, the continuous and demanding energy supply is an area where CHP systems excel, both in reliability and durability. Powered with cutting-edge engine technology, these systems prevent the stalling of production by yielding consistent power, regardless of the power demands of the systems. They are corrosion resistant and built with heat resistant fuels which allow them to withstand the tough industrial environments. Their quick starting abilities, especially in LPG powered CHP systems, provide emergency backup power which ensures the uninterrupted completion of vital industrial processes. This reliability is priceless for industries where shutdowns can be costly.

Smart Integration Boosting Operational Efficiency

Today’s industry is face with great complexity and demands intelligent management and CHP systems have continue to demonstrate that of mastery of fine tuned smart integration .With remote monitoring and automated load management, it is possible to keep track of the system’s performance and make adjustments as needed without constant onsite supervision, optimizing all systems for maximum efficiency. The integration with other renewables like solar and wind to create hybrid systems is seamless and optimizes energy use even further. For these industrials which have advanced and complex energy needs, this smart capability streamlines energy management and enhances operational productivity.

Custom Solutions Tailored to Specific Industrial Requirements

Every industrial CHC systems has particular needs related its production process, scale, and CHC production environment and flow, and CHC systems provide tailored CHC system solutions to such requirements. Auro has full spectrum customization capability including technical consulting, drawing design, assembling and commissioning, and one stop services that tailor to each and every enterprise needs. Be it an off grid industrial site with needing a methanol powered CHC system or an inner city factory needing a low noise Hydrogen CHC unit, the ability to tailor the customization to one’s needs highly increases the system fit with the enterprise’s operational. The personalized approach eliminates the inefficiencies created through a one fit all, thus, maximizes the otal value to the system each industrial user.

Long-Term Value Backed by Comprehensive Support

Investing in units providing combined heat and power (CHP) systems) is a long-term investment and Comprehensive support offered by dependable suppliers is a valued commendable addition. Each unit is thoroughly inspected, tested, and documented at the factory. Valuable quality control pictures and videos from the factory are made and reported to the client. More, a lifetime of after-sale servicing of units is offered and a global network of service centers means all global service requests will be solved swiftly after being called to reduce the units operational downtime. This is the level of reliability support offered to any industrial client which derives their peace of mind from knowing their investment in energy will be in a system that will economically and operationally perform for a long time. This after purchase service is the defining factor of CHP systems value. After CHP systems are purchased, and well after, the value is there is a great retention of quality coupled with value.

Hot News

Hot News