Picking the Most Appropriate Gas Generator Set

Finding a fitting gas generator set is the first step to increasing efficiency. The various types of gas generator sets have different characteristics and functions. Some will be more efficient than others in different scenarios. For example, natural gas generator sets are optimized for natural gas and thus, can save more money on fuel costs than on diesel generator sets. They will work well for places like industrial parks with continuous power demand and stable natural gas supplies. LPG gas generator sets can be used in places like construction sites or telecom towers that need power and are only temporary. The gas is stable, safe, and can be stored and transported in liquid form for long periods of time. Methanol generator sets can be used in remote areas where off-grid power is needed as fuel that is renewable and sourced from biomass is used, thus decreasing the carbon footprint. In places like the central part of a city where the area is to be kept clean, Hydrogen generator sets can be used as they produce no CO₂, which helps the area meet carbon neutral goals. For off-grid power, where remote access is needed, gas generator sets work best. Improving the efficiency of gas generator sets is achievable by selecting the right type to actual use environment and fuel supply.

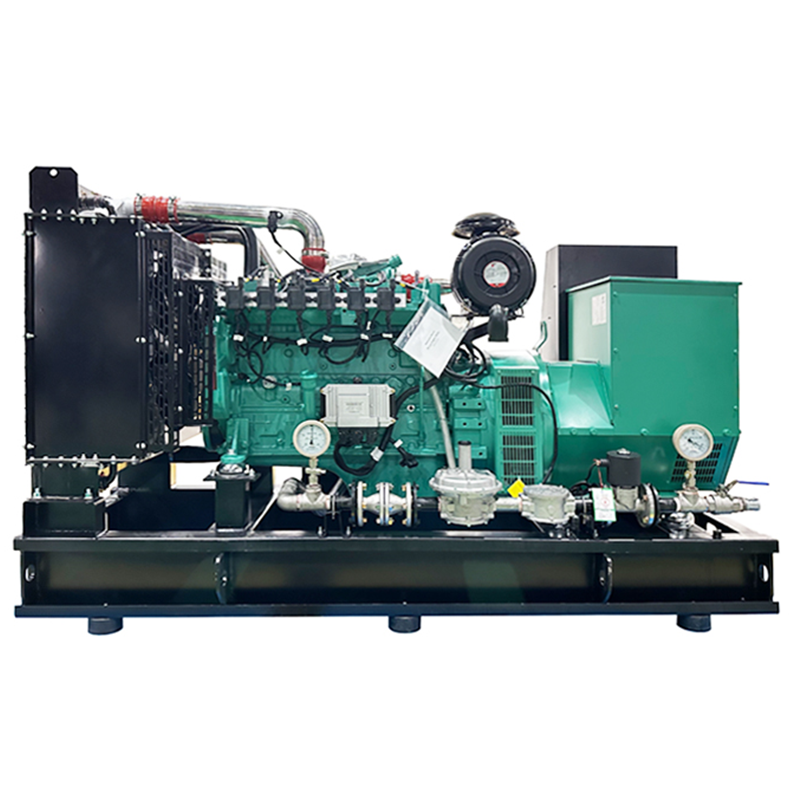

Optimize Fuel Supply and Combustion Systems

Efficient gas generators start with effective fuel and combusiton system management. First, setting a stable, adequate fuel supply is a must. If fuel supply is inconsistent, the output power of the gas generators will fluctuate, causing further loss inefficiency. For example, when using natural gas, the supply and disposal gas line systems, including vent gas pipelines, pipes that the combustion gas passes through, and combustion gas pipelines should be cleared of any potential blockages so that gas is constantly available and can also flow freely into the combustion chamber. Along with fuel supply systems, the combustion systems should be optimized. There is reduced energy waste when advanced combustion technologies allow for more complete combustion. Some gas systems utilize advanced combustion control systems, which adjust fuel and air mixture parameters for more optimal combustion control based on the system load. This lessens emissions while also having a more fuel efficient combustion cycle. This protects the environment while also making fuel efficient systems.

Maintain and Inspect Regularly

Keeping gas generator sets in working and efficient condition requires gas engine generator sets routine maintenance and inspections. Routine oil and filter replacements in conjunction with other maintenance will keep the engine oil and cooling systems functioning properly. Stale oil and clogged filters will increase the friction in the engine and increase energy consumption. Routine electrical maintenance requires the assessment of wire and terminal connections to eliminate poor contacts. This will eliminate electrical losses that will negatively affect the generator set output. In addition to the gas engine generator set maintenance inspections, the generator set testing center will perform the gas generator set performance tests. Examples are tests to determine the generator set output power, fuel consumption, and emissions under varying loads. Routine testing eliminates and resolves problems to maintain optimal generator set performance.

Use Smart Integration Technologies

There is no doubt that smart integration technologies greatly enhance the operational efficiency of gas generator sets. For instance, remote monitoring technology allows operators to track the generator set's power output, fuel consumption, and temperature, and other operational details in real-time. They do not need to be on-site. If they notice an operational anomaly, they can respond quickly and avoid excessive downtime and increased efficiency losses. Automated load management technology adds to operational efficiency. It adjusts the generator set's output power to match the actual load demand, especially during low demand periods. It reduces fuel supply so that no fuel is wasted, and it is able to rapidly increase output power to respond to an increase in load demand. These intelligent fuel adjustments guarantee that the gas generator set operates in the most energy-efficient state. This greatly improves operational efficiency as well.

Choose Appropriate Sites, and Install Properly

The efficiency of gas generator sets will depend on how and where they are installed. While installing gas generator sets, make sure that the foundation is solid and flat. Unstable bottoms can waste operational energy and shorten the equipment's life due to excessive vibrations. So, the location choice should grab attention for this. The gas generator sets will need to be sited in places that are reasonably open to air for equipment cooling ventilation; temperature retention will promote inefficience and damage the generator. Furthermore, the site should be reasonably distanced from flammable and combustible materials to promote safe operational conditions. Sites installing gas generator sets will need to pay attention to safe operational conditions. For instance, hydrogen is flammable. Hence, the hydrogen gas generator set site will need to be controlled for ventilation and fire safety. This will promote operational safety and generator set efficiency.

Hot News

Hot News