Uninterrupted Power Supply: The Backbone of Manufacturing Operations

Manufacturing plants depend on electricity to keep each piece of a production line moving, machinery functioning, and essential steps in a process moving forward. Even brief lapses in electricity can result in expensive downtime, wasted materials, and overdue shipments. During an outage, gas generator sets provide an instant backup power supply. They’re better than many other backup choices since they provide steady output fuelled by generator sets, heavy gas machinery such as assembly line robots, and precise gas controlled inventory sensors. This dependability is most crucial for plants that run 24/7 since even a small production outage can disrupt the entire supply chain.

Cost-Effective Operation:Cutting Down Long-Term Expenses

Manufacturing cost control, especially energy operational expenditures, is crucial. Over long periods, gas powered generator sets cost less than traditional diesel powered generator sets. Besides gas, diesel has less treated prices. Gas, liquefied petroleum gas, and methanol powered plants cost less to maintain. Due to less engine wear, maintenance and major repairs of costly engine components, like replacement parts, repairs are needed less often. Overall, these maintenance cost and time savings are tremendous and helpful to plants marginals. All while plants remain powered.

Low Emissions: Meeting Environmental Standards and Sustainability Targets

There are many regulations and consumer demands that require reductions in the manufacturing industry's environmental footprint. Of the alternatives to diesel generators, gas generator sets have lower harmful emissions and are more environmentally friendly. Natural gas and LPG models release lower amounts of NOx, CO, and particulate matter; and methanol units can be made from renewable biomass to reduce carbon emissions. The most environmentally friendly option are gas generators that use Hydrogen powered gas generators. They have no CO2 emissions when run on green Hydrogen made from solar or wind energy. Implementing these generator sets, manufacturing plants can meet stringent environmental regulations, dodge costly fines, and increase their image as green operations. This is crucial for attracting customers and investors who are concerned about the environment.

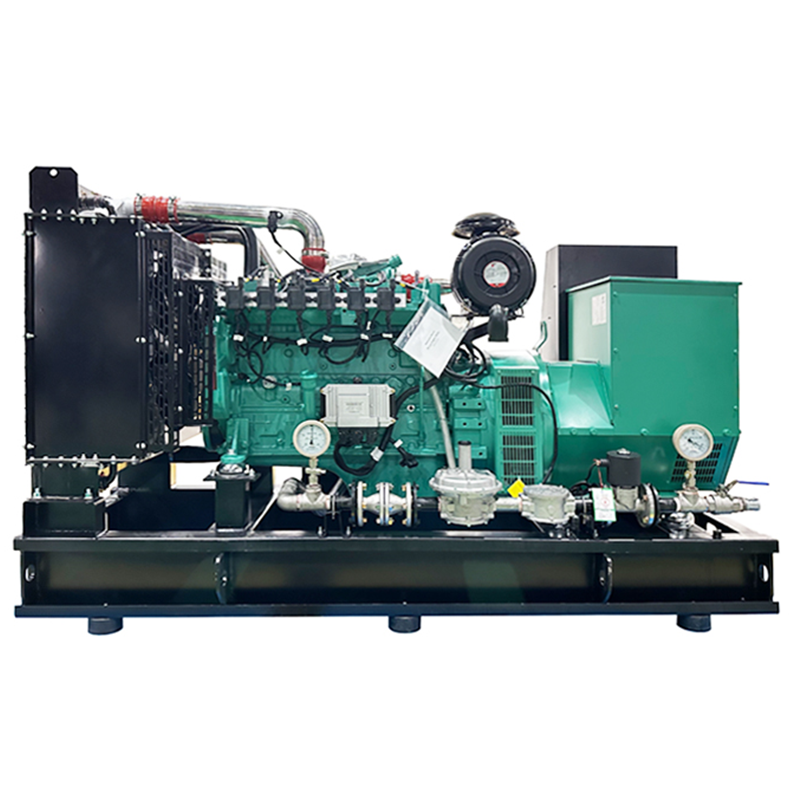

Flexible Applications: Meeting the Unique Needs of Various Plants

With different shapes and sizes, plants have different power requirements, and operational conditions as well. Gas generator sets have an incredible degree of flexibility. They range from very small units that can power individual machines, or systems that need to be backed up to very large, containerized systems that can power an entire plant. Different fuel types also add to this flexibility: plants connected to a gas pipeline can use natural gas models, but it is also possible to use LPG units at temporary sites or places with no pipeline access. Methanol and hydrogen generators are also used in plants to achieve full carbon neutrality, or in off-grid areas. Because of this gas generator versatility, plants of any size, anywhere in the world, with any sustainability target can achieve their gas generator set.

Smart Technology: Improving Operational Efficiency

In order to improve efficiency and streamline operations, modern manufacturing plants are using smart technology. Generator gas sets are another technology which improves efficiency and even integrates into smart systems. Because of remote monitoring, gas generators can inform plant managers about any changes to performance, fuel levels, and maintenance which can be accessed through control rooms and mobile devices. Automation fuel load management systems within gas generators ensures maximum efficiency by preventing fuel waste and unnecessary costs. Smart technology within gas generators improves management efficiency, predictive maintenance, and energy informed decision-making. For plants which prioritize smart manufacturing, gas sets generators provide competitive value.

Reliable After-Sales Support: Ensuring Peace of Mind

You need a gas generator set for a long time and need to be certain there is support for when things go wrong. Trustworthy suppliers will provide complete after-sales service including lifetime warranties and worldwide service coverage. To maintain quality, generator sets get tested before delivery, and a video and photo certified quality documentation is sent to you. If an issue should ever arise, local service offices are on hand to send a technician, eliminating any possible downtime. Support like this is critical for manufacturing because of the risk of generator failure and the need to backup power. Peace of mind comes when gas generator sets come with reliable after-sales support.

Hot News

Hot News