To safely operate natural gas generators and protect their parts from being damaged, fuel purity is crucial. The gas being supplied must contain a minimal number of impurities, and the contaminants must meet certain guidelines, especially regarding sulfur compounds, moisture, and particulates. The concentration of sulfur, for instance, must be kept below 20 mg/m³ to avoid the corrosion of the engine parts and the clogging of fuel injectors. If there is too much moisture present, the fuel system could be blocked due to ice formation during cold weather, which would restrict the flow of fuel and impair power output. Dust and dirt particulates can scratch the internal parts of the engine, which would lower the generator’s life and increase the need for maintenance. If purity standards are met, the generator will operate efficiently and the failure of any part will be predictable.

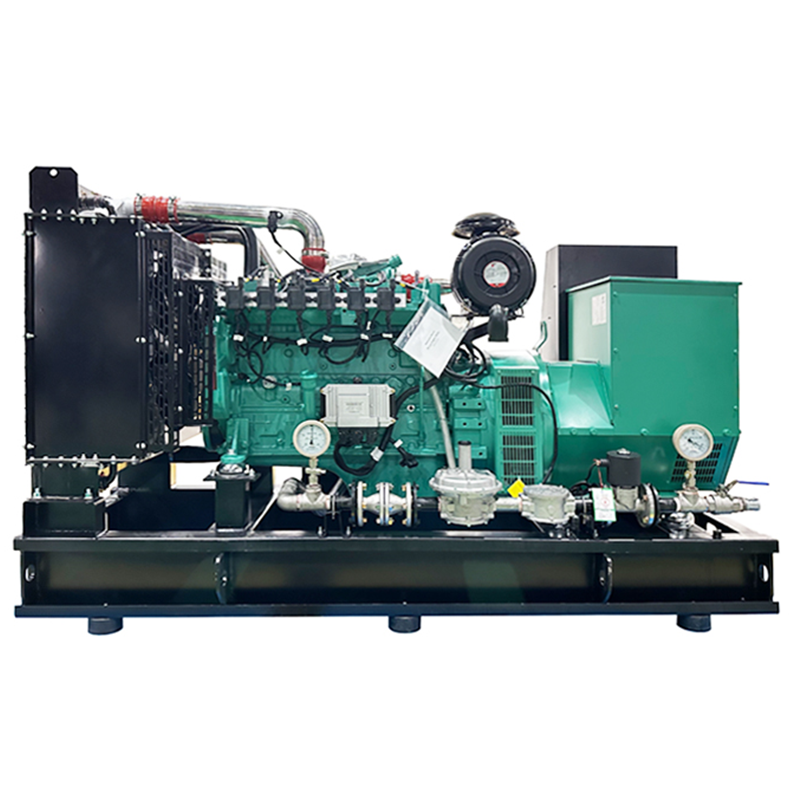

Flow Rate and Pressure Specifications

Adequate fuel pressure and flow rate are essential for natural gas generators to power reliably. Different generator sizes and types will have different specific gas pressure requirements. However, most generators have gas pressure requirements of 3.5 psi to 7 psi at entry points. If gas pressure is too low, the generator will not get enough fuel to meet power demands and will lose power or completely shut down. If gas pressure is too high, it will rupture the fuel regulator and other protective parts. Also, fuel flow rate supplied must equal the generator’s maximum fuel consumption. For example, during full-load running, 100 kW natural gas generators will require flow rates of 10 cubic feet per minute (cfm). For dependable generator performance, gas supply should maintain adequate flow rates and pressure.

Requirements For Different Natural Gas Mixtures

Every type of natural gas mixture uses varying combustion means, natural gas composition must be up to par for the generator to be combustion efficient and limited on emissions. Natural gas must have a minimum of 85% methane for a efficient fuel mixture as well as the main fuel which means it must to be burning clean and burning efficiently to meet rigid burning emissions. Ethane and propane can be burning in the fuel but must be in small percentages mostly less than 10%, too much will change burning combustible fuels. If the fuel combustible are incomplete burning, it will increased burning emissions of NOx and CO and decreased the generator combustion efficiencies. Also there must be fuel burning in natural gas.

Compatibility of Natural Gas With Generators Components

To maintain the long-term dependability of a generator’s fuel system. Natural gas must be compatible with the materials and components used in the fuel system. Pipes, hoses, and seals, and other fuel system components, are made of stainless steel, brass, or a special polymer. Natural gas is non-corrosive, and the impurities in the gas, such as hydrogen sulfide, could corrode iron and form corrosive compounds. This corrosion could cause a hazardous leak and disrupt the generator’s operation, as weak pipes could become hazardous and leak. Antifuels that solvents or oils can dissolve a fuel system’s seals and hoses. Generators components improve fuel system lifespan and upkeep money.

Safety and Compliance Considerations

Using a natural gas generator means you must always use gas safety and compliance standards. The gas supply must meet safety standards at the local and international level. The United States National Fire Protection Association and International Organization for Standardization (ISO) international standards outline safe gas storage, transportation, and delivery to the generator, and the generator gas fueling systems must be safe from gas leaking and the potential for explosion. For instance, gas pipelines must be properly insulated, regularly pressure tested, and contain quick shut-off valves at strategic locations to stop the gas flow in emergencies. The generator must meet local environmental laws for its NOx, CO, and particulate matter emissions. The safety and compliance standards using the fuel protect the people and property, and, for the enforcement authorities, make the generator legally operable in the gas supply location.

Hot News

Hot News