Know the Essential Characteristics of LPG to Handle It Safely

Every Safe LPG Handling Guide should include the LPG basic characteristics. As an example, the specific pressure of the LPG cylinder should the safe kept in a cool place. Additionally, the LPG transporting cylinder would also need a well ventilated area. Another safe handling would be to check if there are any leaks from the engine. LPG gas cylinders should be stored away from the heat and sunlight and at cool temperatures. This is suld also be well vented as the gas is stored under peur. Also to avoid any LPG build up in the area ensure there is Provided a Minimum Fuel Intake area. Also, cylinder gas leaks must be cleaned as LPG is heavier than air.

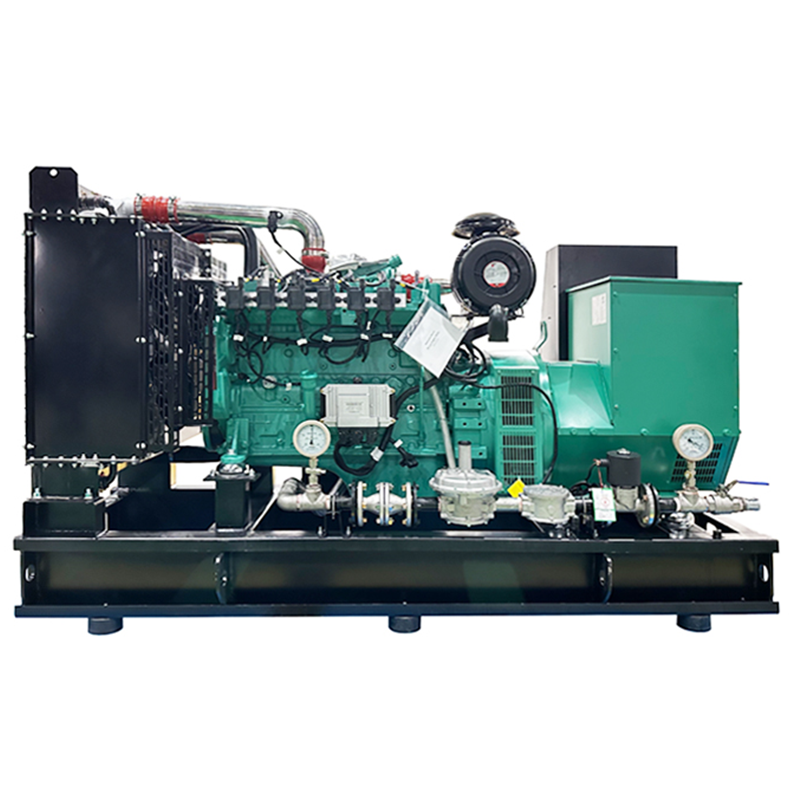

Routine Fuel System Inspections

Since the fuel system is the core of an LPG gas generator, routine inspections are important. Examine the fuel lines first. Check for signs of wear, brittle and damaged lines. If you find any cracks, you should replace the line right away. Avoid patching them. The next component to check is the fuel pressure regulator. The regulator controls the LPG flow from the cylinder to the engine. An engine running poorly can be the result of an unstable fuel supply due to a faulty pressure regulator. To check the regulator, run the generator at varying loads and listen for sputtering to determine if the engine is unstable. The fuel filter is another essential component. Filters that are clogged will reduce fuel efficiency because fuel flow will be restricted. Depending on the use of the generator, filters should be cleaned or replaced every 50 to 100 hours of operation. Lastly, check the cylinder valve for smooth operation. If the valve feels stiff, lubricate it. This will prevent damage to the cylinder valve and will ensure a tight seal when the valve is closed.

Engine Maintenance to Ensure Longevity

Taking care of the engine means the LPG generator will run effectively for many years. To start, change the oil. Most LPG generators need oil changed every 100 to 200 hours of operation and follow the manufacturer’s oil change instructions for the correct oil type and change intervals. Engine oil that hasn’t been changed will overheat and wear the engine parts because it will dirt and grime build up which creates more friction. You should also check and fill the oil before starting every time. The oil goes very quickly and the engine will suffer major damage without oil. After that, check the air filter. Less air means less combustion, which means less power. After every 25 hours of operation, use compressed air to clean the filter. The spark plugs are also really important. Hard starting and misfiring are key signs that spark plugs need checking. After every 150 hours of operation, check and clean the spark plugs. Also check that they are not damaged, replace them if necessary and gap them correctly according to the manufacturer’s instructions.

Ensuring Safe Operation of Electric Systems

To ensure user safety and determine the safety of the performance of the generator, the electric systems should first be evaluated. If the generator has a battery, first check the generator battery. Inspect the battery terminals for corrosion. If you see white or green build-up, this corrosion can be removed with a wire brush and a mixture of baking soda and water. Also, make sure the terminals are tight because loose terminals can cause poor connections, which leads to starting issues. Also check the battery voltage regularly. If a battery is weak, the generator will not start when needed. After checking the battery, check the wiring and electrical connections next. Look for loose wires, see if the sliding wires are worn down, or burnt areas. These can cause electrical shorts and fires. Replace any damaged wires immediately Tighten any loose connections first. Test the generator’s output voltage next. Use a multimeter to check the voltage at the outlets when the generator runs at full load. The voltage should stay within the manufacturer’s recommended range because if the voltage is extremely high or low, it will damage the connected equipment. Lastly, circuit breakers should be checked. Confirm that when there is an overload, the circuit breakers trip, to confirm that the generator, and the plugged-in devices, are protected.

Here's how to Prepare for All Weather Maintenance

Taking care of LPG generators to keep them reliable during every season requires attention to detail. Before winter, drain the fuel system of any water to avoid the possibility of freezing, which can then crack the pipes and valves. If the manufacturer suggests, put a fuel stabilizer in the LPG to keep it from degrading during storage. Don't forget about the generator’s cooling system too—check that the coolant level is full, and the radiator is free from any debris. Even in cold weather, a blocked radiator can overheat the engine. In snowy areas, ice and snow vent blockage can vent and intake areas—check, unclog, and vent regularly to avoid engine heat in the winter. Before summer arrives, thoroughly clean the generator of any winter dust, debris, and dirt that has built up. Make sure the fan and cooling system can handle the heat—high temperatures can cause the engine to overheat so appropriate cooling is vital. Examine the generator’s enclosure for damage as well to avoid summer storms cracking, so it will bring in rainwater and cause electrical problems.Post Use Maintenance for Long-Lasting Performance

Proper generator maintenance right after use can prolong generator life and prevent problems. When conducting maintenance, remember to first wait for the engine to cool. Working on hot engines can damage components, and hot parts are a burn risk. After the engine cools, maintenance includes cleaning the generator. The case must be wiped with a damp cloth to remove dust, dirt, and debris. Don’t forget the vents and intake areas—restricted airflow vents can reduce overall efficiency. After every use, check the fuel level. When the generator will not be used for long periods, don’t be a fuel tank with LPG; stagnant fuel may degrade and cause fuel system problems. It is best to use the fuel or drain it before the generator is placed in storage. Look for damage on the generator for maintenance, paying attention to dents, cracks, or loose parts, and resolve the small issues to prevent them from becoming larger, costly, and more complex problems. Finally, store the generator in a dry and ventilated area.

Hot News

Hot News