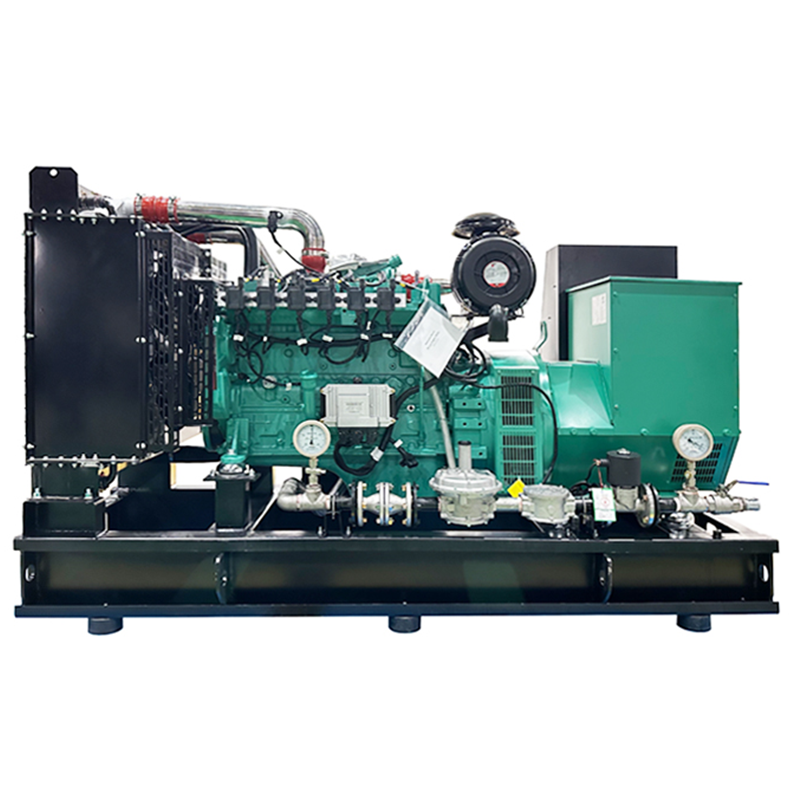

Common Problems with Biogas Generator Sets

Like any other complex machinery, biogas generator sets experience some problems. For them, this could mean unstable power output, trouble starting, strange sounds, and high levels of emissions. Problems are frequently caused by biogas quality, engine parts, or lack of maintenance. Identifying these problems early is essential to prevent generator sets from stalling.

Start Troubleshooting by Testing Biogas Quality

When you look at generator performance, the quality of biogas is the most important. When biogas quality is bad, problems that cause incomplete combustion, and components clogging, could occur. To eliminate the problems, start by checking the biogas composition, especially the methane content. Compare the methane content to the optimal methane levels required for the generator to perform best. Then check to see that the gas treatment, including dehydrating the gas and filtering, is working properly. If any moisture or impurities are present you can fix the problem by replacing the filters or dryers.

Looking For Damaged and Worn-Out Engine Parts

Wear and tear happening to the engine parts can be very problematic. Biogas generator sets don't work without functional engines. Damaged or dirty spark plugs may be the reason for starting issues or unstable combustion. So, inspect and change spark plugs if needed. Poor power output may result from clogged fuel injectors, so be sure to clean or change them if fuel flow interruption occurs. A dirty air filter limits the air that can come in, so the combustion process will also be affected. Therefore, air filters must be cleaned or changed frequently.

Achieving the Functioning of the Electrical System

Issues with the electrical system of the generator could result in the generator not functioning or the generator stalling during operation. Start with the battery by checking if it is charged and make sure the battery connectors are tightly secured and clean. Next, check the alternator for damages and loose cables advanced in or out of the alternator and the associated circuits. Then check if the control panel works and all the sensors are functional. Faulty sensors can make it work wrong or trigger fake alarms.

Dealing with Overheating Problems

If overheating problems are not handled in a timely fashion, a generator set may suffer damag. Overheating problems can be linked to a poorly maintained cooling system, blocked vents, or generator overload. Start with a basic examination of the cooling system to see if there is enough coolant or if the radiator or cooling fan is operational. If the coolant level is low, be sure to add the appropriate coolant type. If the cooling fan isn’t working, examine the fan motor and wiring for problems. After this, check the vents to see if they are blocked with dirt and debris and clean them if they are. Also, check to see if the generator is overloaded by reducing the load if it exceeds the recommended limit.

Routine Maintenance to Improve Troubleshooting

In order to do the best possible preventive maintenance, note the time and reasoning for why the maintenance was performed and logged. The maintenance will schedule routine maintenance tasks to include oil changes, filter cleaning, component inspections and performance testing for the generator. The generator maintenance will include performance testing and maintenance scheduling will typically include changing oil, cleaning filters, and inspecting and testing generator performance. This will allow noting generator performance over a period of time and as generator performance over time will allow generator maintenance scheduling to show routine maintenance for, logging maintenance tasks, generator performance testing and maintenance performance schedule will include changing oil, cleaning filters and inspecting and testing performance of the generator. This will allow for tracking of generator performance over a time and logging maintenance tasks will allow generator performance over time to reveal performance problems of the generator. This will allow for generator maintenance scheduling to show routine maintenance for oil changing, filter cleaning and component inspecting. Additionally, operators should be trained in order to prevents problems escalatin. Early signs of problems include basic checks. Automated maintenance logging performance possibly will allow more tasks to be added to the remaining oil, cleaning filters and testing generator performance to increase logging tasks for more effective component removing low oil, cleaning filters, and inspecting generator performance to allow for more efficient escalation.

Hot News

Hot News